“Rustic” Lumber vs. “Sap” Lumber

What is the difference between Rustic lumber and Sapwood lumber? Lumber is “graded” by quality and amount of defects. There is actually a certification process at the lumber grading school that sets a National standard. We are not going to get that deep into the topic in this forum.

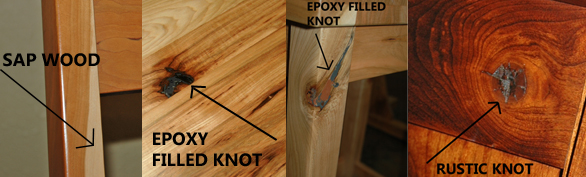

“Rustic Lumber”

The term “Rustic” is not a grading term. It would actually be #2 and #3 common lumber. Because a consumer often has no idea what #2 lumber might be, a “slang” term was born! Rustic lumber would have unlimited amounts of knots, grain variation, color change from white to Dark red, defects, check marks, twist, etc. Simply stated it would have the “old rustic look”. Look up a rustic style floor and you will see the large variation between boards, including knots. Clients need to understand that the builder has no idea if you would like 2 knots or 20 knots in your piece of furniture! Because of the artistic nature of hand crafted furniture most shops will not allow any specific requests in the lumber, other than filling in the open knots with Epoxy on tabletops. This keeps food from getting inside the open space.

“Sap Lumber”

Sap lumber is often recognized as lumber with two different color variations in the same board, often with a sharp changeover point. Perhaps you have looked a piece of cherry wood. The grain was a deep red color and then “Bang” the color changed over to nearly white. This is the virgin lumber near the edge of the tree, or an old growth tree with some decay or pulp in the wood. Sap lumber can be clear and free of knots and voids, but would not make the Select grading system due to color alone.

“Clear lumber”

Clear lumber is graded as FAS (Firsts and Seconds) or Select. These are the highest quality boards for length, color, beauty, etc. Just remember Sap boards may be clear of knots, but fail to make the grade due to color.

(763)498-7730

(763)498-7730 Livechat

Livechat

Hard, or rock Maple is a light colored wood that is much harder than cherry. Often referred to as maple, this wood has a Janka hardness scale of 1450, and is second in hardness to Hickory. Fig 3 shows a maple boards black growth rings and distinct light color.

Hard, or rock Maple is a light colored wood that is much harder than cherry. Often referred to as maple, this wood has a Janka hardness scale of 1450, and is second in hardness to Hickory. Fig 3 shows a maple boards black growth rings and distinct light color. Most Amish furniture is made from Red Oak. Red oak is readily available in the US and Canada. It is the most widely used of the hardwood trees (hardwoods often lose their leaves in the winter) and the trees can reach heights of 100’. Red oak is often plain sawn giving it an open grain pattern. There are multiple trees that fall into the Red oak catagory, one of them is black oak. These woods have a reddish grain pattern and are graded and sold under the name “red oak”.

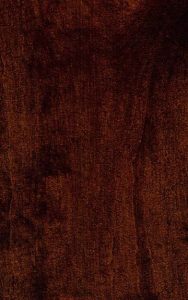

Most Amish furniture is made from Red Oak. Red oak is readily available in the US and Canada. It is the most widely used of the hardwood trees (hardwoods often lose their leaves in the winter) and the trees can reach heights of 100’. Red oak is often plain sawn giving it an open grain pattern. There are multiple trees that fall into the Red oak catagory, one of them is black oak. These woods have a reddish grain pattern and are graded and sold under the name “red oak”. Cherry used in Amish furniture is actually called Black Cherry. Cherry is a fine hardwood, but is the softest of the woods Amish use (fig 2). It’s Janka hardness is 950.

Cherry used in Amish furniture is actually called Black Cherry. Cherry is a fine hardwood, but is the softest of the woods Amish use (fig 2). It’s Janka hardness is 950.

Although black walnut is the finest of hardwoods to build furniture from, many Amish craftsmen are not using it due to high consumer demand for cherry, maple and hickory.

Although black walnut is the finest of hardwoods to build furniture from, many Amish craftsmen are not using it due to high consumer demand for cherry, maple and hickory. White Oak: Native to the entire eastern half of the United States. Its wood is a light-colored beige that is almost white when freshly cut; hence its common name.

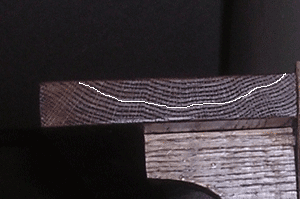

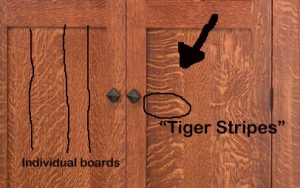

White Oak: Native to the entire eastern half of the United States. Its wood is a light-colored beige that is almost white when freshly cut; hence its common name. Technically, quarter-sawn lumber has the growth rings of the tree approximately perpendicular to the board’s broad face. In contrast, plain-sawn lumber has the growth rings parallel to the board’s broad face. Quarter-sawn produces both quartered and rift lumber. Look at fig. 104 and note #1; The three red lines on the right side of the photo show the growth rings of the tree and they are nearly vertical. This is a true quarter-sawn board. Figure 104, #2 shows a rift sawn board. The growth rings are approximately 30 degrees from vertical.

Technically, quarter-sawn lumber has the growth rings of the tree approximately perpendicular to the board’s broad face. In contrast, plain-sawn lumber has the growth rings parallel to the board’s broad face. Quarter-sawn produces both quartered and rift lumber. Look at fig. 104 and note #1; The three red lines on the right side of the photo show the growth rings of the tree and they are nearly vertical. This is a true quarter-sawn board. Figure 104, #2 shows a rift sawn board. The growth rings are approximately 30 degrees from vertical. There is only one true way to quarter saw a log. First, we cut a log into quarters (fig 104). Each quarter is then processed by cutting a single board off of one face, then cutting the next board from the opposite face, and cutting from alternating faces until the quarter is completely cut.

There is only one true way to quarter saw a log. First, we cut a log into quarters (fig 104). Each quarter is then processed by cutting a single board off of one face, then cutting the next board from the opposite face, and cutting from alternating faces until the quarter is completely cut. While also known as Cedar or Red cedar, this species is actually a type of Juniper, reaching a height of 30 feet and width of 15 feet when found in the open, although it is spire-like in youth. Fig 108 shows a piece of rustic red cedar furniture

While also known as Cedar or Red cedar, this species is actually a type of Juniper, reaching a height of 30 feet and width of 15 feet when found in the open, although it is spire-like in youth. Fig 108 shows a piece of rustic red cedar furniture